Reusing wastewater for construction

At CI we keep looking for ways to be a more sustainable project. Construction uses a lot of water: for example, to depress dust on site and hose down equipment and plant. It’s also used for bentonite batching, creating a drilling fluid used to lubricate the TBM cutterhead and stabilise the ground being drilled.

Our latest initiative is the Māngere Recycled Water Plant (RWP), on our Māngere Pump Station site. The RWP is a small water reuse plant on a pilot scale consisting of two treatment streams.

The first stream is a ‘main treatment process’, treating sewage effluent to the standard for use in construction. We aim to produce 500,000 litres per day specifically for use above ground and in the main CI tunnel.

Producing recycled water for construction use has two major benefits: it reduces both the volume of treated effluent being discharged into the Manukau Harbour and reduces reliance on Auckland’s main water supply network.

The second treatment stream is a small demonstration plant trialling new technologies to produce treated water so it can be used for drinking. Its aim is 30,000 litres per day of potable drinking water for testing and analysis. This plant, a first for the country, is a further Watercare CI initiative to demonstrate and prove various technologies for producing high-class, reuse water from sewage effluent.

Photo: Water reuse plant machinery ready for operation

Taking practical steps to reduce, reuse and recycle

At CI (Central Interceptor) we focus on the efficient use of resources such as energy, materials and water on reducing waste and on reusing what would otherwise be dumped.

As you might rightly expect from our name, Watercare is active in reducing our water consumption. We can do this by using non-drinkable (non-potable) water. We collect rainwater on site, use bore water and reuse water we’ve already used onsite for construction. In another major initiative, we are building a plant to treat and re-use wastewater from our Māngere wastewater treatment plant. This water will help run the TBM as it bores forward from our Māngere construction site.

As with water, using less energy is vital for us. For example, we’ve reduced driving distances of trucks carrying away our dirt and soil. We also dry this spoil on-site to reduce the weight of transported material. We also look to use electric equipment, wherever possible, rather than use fossil fuels. The locomotives transporting people, equipment and rocks and dirt (spoil) up and down the tunnels are electric battery-powered and as a result improve the air quality in the tunnel. CI is also about to introduce electric trucks for hauling tunnel spoil to Puketutu Island in Māngere.

For some of our construction sites we’ve had to buy land with existing houses on and subsequently remove them. Rather than the traditional smash and bash approach which involves taking all the material to the dump, we now deconstruct buildings. We systematically take them apart so most of the material can be reused. For example, from two houses in Grey Lynn we kept 91% of the material out of landfill, with the doors being sent to Tonga for reuse. Deconstruction is also quieter for our neighbours than demolition.

Photo: Rather than demolish we deconstruct and recycle

Photo: Rather than demolish we deconstruct and recycle

We can’t talk about sustainability without discussing climate change: it has been a major factor in our thinking and shows in our design planning. Our designers took climate change into serious consideration in the tunnel’s design, its size, and the materials it is built from. This means that the tunnel can ride out more intense storms and cater for our city’s expected increase in population.

Electric haulage trucks on their way

We continually look for new ways to be more sustainable with our project resources. The project is on the road to making our heavy vehicle fleet greener thanks to a $500,000 grant from the Energy Efficiency & Conservation Authority (EECA) which will be put towards buying three electric trucks. (Our bid was one of the successful 22 bids out of 55.)

Anticipated to arrive early next year, the e-trucks will transport more than 66,000 tonnes of earth from CI sites

, reducing project emissions by more than 300 tonnes - that's the equivalent of driving from Cape Reinga to Bluff more than 800 times.

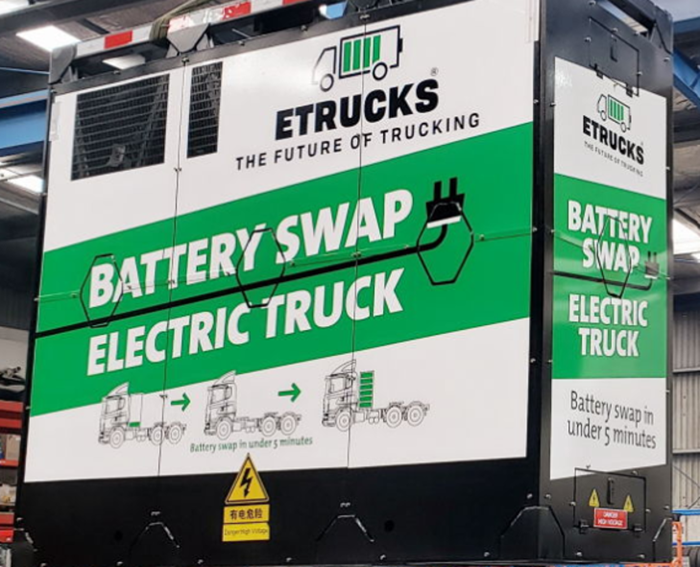

Photo: E-truck battery ready for installation

For every 100,000 km travelled the trucks will save 40,000 litres of diesel. This will reduce CO2 emissions by more than 300 tonnes annually as the trucks produce 79% less carbon than diesels. This is the equivalent of powering some 400 average homes for a year!

The vehicles aren't as noisy as diesels either, which will be fantastic for the teams working in residential areas. They also have lift-off battery swapping capability, so they don't have the usual downtime while charging: they can have the battery swapped out for a fully-charged one in 5 minutes – the same time it would take to re-fuel with diesel.

Our earth-moving partners, Fulton Hogan, has been upskilling to manage the heavy trucks. Two of the trucks have arrived in the country with the third due shortly. They will shortly receive their CI project livery.